01. Asbestos Use in Insulation

Why Was Asbestos Used in Insulation?

Asbestos was used in a variety of insulation products for nearly a century. From the mid-1860s through the late 1970s, the mineral was used in many types of insulation. Common areas for this insulation include buildings, machinery, pipes, boilers and more.

Asbestos insulation is one of the largest sources of asbestos exposure. Thousands of workers and residents have been exposed to the dangerous material. Asbestos exposure can lead to serious health problems, including mesothelioma.

Asbestos diseases can develop after an individual inhales or ingests the microscopic fibers. This often happens when friable (crumbly) asbestos products are disturbed. Once disturbed, the mineral fibers may become airborne and can easily enter the body.

Asbestos Insulation History at a Glance

- Other Names: Block insulation, fill insulation, loose insulation, pipe insulation, spray-on insulation

- Years of Manufacture: 1866 – 1990

- Military Use: Aircraft, military barracks, ships, shipyards

- Places Used: Attics, boilers, buildings, ceilings, factories, floors, manufacturing floors, residential buildings, sheet packing, ships, walls

- Asbestos Use Banned: No

- Noteworthy Brands: Kaylo, manufactured by Owens-Illinois, Inc.; Unibestos manufactured by Pittsburgh Corning; Zonolite manufactured by W.R. Grace

Asbestos Insulation Regulations

From the 1970s through the 1990s, U.S. federal agencies began to regulate asbestos. Notable regulations around asbestos-containing materials (ACMs) include:

- In 1973, the Environmental Protection Agency (EPA) banned spray-applied ACMs used for fireproofing and insulating.

- In 1975, the EPA banned the installation of asbestos pipe insulation and asbestos block insulation on facility components, such as boilers and hot water tanks.

- In 1977, the Consumer Product Safety Commission (CPSC) banned asbestos in artificial fireplace embers and wall patching compounds.

- In 1978, the EPA banned spray-applied surfacing materials not covered under the 1973 ban.

- In 1990, the EPA prohibited spray-on materials containing more than 1% asbestos.

The mineral may still be present in products manufactured before these dates. Today, certain types of insulation may still contain up to 1% asbestos, according to EPA guidelines.

Dangers of Asbestos in Insulation

Asbestos exposure can lead to the development of many related diseases. Exposure to asbestos insulation may cause any of the following illnesses:

- Asbestosis

- Asbestos cancer

- Laryngeal cancer

- Lung cancer

- Mesothelioma (pleural, peritoneal and pericardial)

- Ovarian cancer

- Pleural plaques

- Pleural thickening

A study of insulators in Ireland found increased mortality rates due to asbestos diseases. The researchers followed 162 insulators from 1940 through 1975. They found elevated mortality from mesothelioma, asbestosis and bronchial carcinoma.

High asbestos exposure levels do not necessarily guarantee an asbestos disease. However, asbestos exposure is the primary cause of mesothelioma. Any level of exposure may lead to an asbestos disease, such as mesothelioma or asbestos lung cancer.

U.S. agencies have tried to curb asbestos exposure with regulations and standards for handling the mineral.

02. List of Asbestos Insulation

List of Asbestos Insulation Products

Many products produced before 1980 contained asbestos. Asbestos products were used across several industries, including construction, metalworking and shipbuilding. Asbestos insulation was used in many industries that included manufacturing or high temperatures in their processes.

Click on any of the asbestos insulation products below to see a list of brands and manufacturers.

- Asbestos canvas

- Asbestos rope

- Asbestos sheets

- Asbestos spray

- Asbestos wool

- Attic insulation

- Block insulation

- Calcium silicate

- Cork covering

- Insulation

- Lagging

- Marinite

- Millboard

- Pipe insulation

- Rollboard

- Sheet packing

- Silicate calsilite

- Sponge block

- Vermiculite

- Wicking

Types of Asbestos Insulation

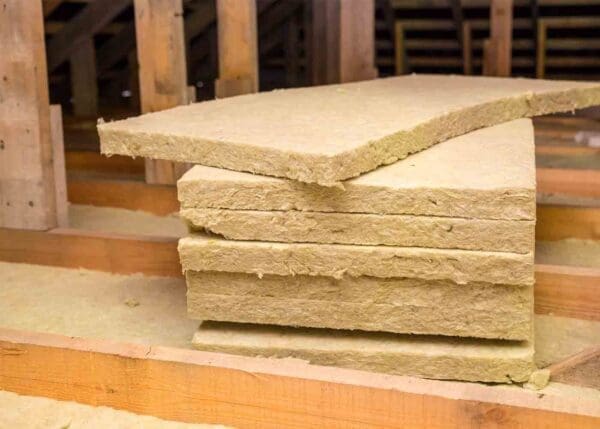

Asbestos insulation can be divided into four main types. The mineral was used for its durability and resistance to heat and chemicals.

Other types of insulation products that may contain asbestos include cement, electrical panels, plaster and certain brands of batt insulation.

In addition to the mineral’s ability to withstand high temperatures, ACMs were cost-effective to produce. As a result, many companies included it in their products.

Insulation products often contained high concentrations of asbestos. For instance, some millboard products reportedly consisted of upwards of 85% asbestos. These products were used frequently in the construction of residential and commercial buildings.

Asbestos insulation has been found in businesses, factories, homes, hospitals and schools.

Asbestos insulation was also used to line other products, such as boilers, steam pipes and valves. These industrial uses of asbestos insulation were common in factories and plants across the United States.

A wide range of manufacturers included asbestos in their insulation materials. These manufacturers often sold products to other asbestos companies to distribute and install. Companies also acquired and sold brands, which can complicate tracking the responsible manufacturer.

Over the years, many companies produced and sold asbestos insulation.

Asbestos companies were often aware of the risks of asbestos exposure but chose not to protect their employees. As a result, companies exposed thousands of workers and consumers to asbestos-containing materials.

03. Insulation & Asbestos Exposure

Who Is at Risk of Asbestos Exposure From Insulation?

Asbestos insulation exposed thousands of workers, consumers and bystanders to the harmful mineral. Some occupations were in almost constant contact with asbestos products at work. These workers are more likely to develop diseases, such as mesothelioma.

For a large part of the 20th century, asbestos insulation products were unavoidable in certain settings. For example, the U.S. Navy required asbestos use aboard its ships for decades.

Other occupations may have only occasionally encountered asbestos. However, any amount of asbestos exposure can be dangerous.

Occupational exposure is one of the most common ways to come into contact with asbestos. However, secondhand exposure can be just as dangerous. This can happen when asbestos fibers settle on the clothing of asbestos workers. The fibers may later be disturbed and inhaled by family members and loved ones. Secondary exposure can still cause mesothelioma and other asbestos diseases.

04. Asbestos Lawsuits

Asbestos Lawsuits, Settlements & Other Compensation

Asbestos exposure victims with an asbestos-related disease may be eligible for compensation. Victims can seek justice from the parties responsible for their exposure.

Compensation can come in many forms. Asbestos victims may be able to receive awards from a trust fund claim, lawsuit or settlement.

Notable asbestos insulation companies with trust funds include:

- Celotex Corporation: Celotex Asbestos Settlement Trust

- Combustion Engineering: Combustion Engineering 524(g) Asbestos Personal Injury Trust

- Garlock Sealing Technologies: GST (Garlock Sealing Technologies) Settlement Facility

- Johns-Manville Corporation: Manville Personal Injury Settlement Trust

- W.R. Grace: WRG Asbestos PI Trust

Claimants can file directly with these trusts to receive compensation. An asbestos lawyer can help individuals gather the necessary information for their mesothelioma claims. More than $30 billion is set aside in various asbestos trusts.

However, many asbestos companies do not have trust funds. In this instance, individuals may wish to file an asbestos lawsuit. Lawsuits can result in asbestos settlements or verdicts.

Insulation Case Set Precedent for Future Asbestos Litigation

One of the first successful asbestos insulation cases involved an industrial insulation worker.

The worker, Clarence Borel, was exposed to asbestos throughout his 30-year career. From 1936 to 1969, he was in contact with asbestos insulation daily. He was not required to wear a respirator or any personal protective equipment (PPE).

In his deposition, the worker testified he often inhaled asbestos dust from insulation. However, he did not know how dangerous the dust was.

“Yes, I knew the dust was bad,” Borel said. “But we used to talk [about] it among the insulators, [about] how bad was this dust, could it give you TB, could it give you this, and everyone was saying no, that dust don’t hurt you, it dissolves as it hits your lungs.”

As a result of asbestos exposure, Borel developed asbestosis and mesothelioma. In 1969, he filed a case against 10 asbestos companies. Four defendants settled out of court. The other six continued to trial.

The remaining companies involved in Borel’s case were:

- Armstrong Cork Corporation

- Fibreboard Paper Products Corporation

- Johns-Manville Corporation

- Philip Carey Corporation

- Pittsburgh Corning Corporation

- Ruberoid Corporation, a Division of GAF Corporation

Borel passed away before the case concluded, so his wife stood in as the plaintiff. All defendants were found liable and his wife received the jury award.

The American Museum of Tort Law considers this case an important landmark in asbestos litigation.

“Borel v. Fibreboard Paper Products Corp. was the first successful suit by an insulation worker against asbestos manufacturers. The success of the Borel case inspired a large number of lawsuits and facilitated controlling hazardous materials in the workplace through product liability actions. Subsequently, hundreds of thousands of asbestos victims, mostly workers, filed lawsuits in courts across the country.”

– American Museum of Tort Law

Compensation Following Exposure to Asbestos Insulation

Lawsuits are one avenue mesothelioma patients can seek compensation. Notable asbestos insulation-related lawsuit verdicts include:

- In September 2020, a California jury awarded a plaintiff $2.6 million. The plaintiff was a retired Navy veteran. He developed mesothelioma from exposure to asbestos insulation during service. He was exposed to insulation manufactured by Metalclad Insulation Corporation.

- In October 2018, a North Carolina jury awarded one of the largest verdict amounts for an asbestos insulation case. The jury awarded the family of an asbestos victim $32.7 million. The victim died of mesothelioma resulting from workplace exposure to asbestos insulation. He worked in a tire plant, where he was exposed to asbestos pipe insulation installed by Covil Corporation. Though Covil Corporation tried to appeal the verdict, it was affirmed by several federal appellate courts.

- In September 2017, a Massachusetts jury awarded a former power plant worker $7.55 million. From 1968 to 1976, the plaintiff worked as an equipment operator at a New Hampshire plant. During his work, the plaintiff was exposed to Kaylo brand insulation produced by Owens-Corning Fiberglas. The insulation was installed by New England Insulation, the defendant in the case. The plaintiff’s workplace exposure led him to develop mesothelioma. The jury ordered New England Insulation to pay the man damages for his exposure and disease.

Experienced mesothelioma lawyers can help mesothelioma patients and other asbestos victims receive compensation. Lawyers will assist plaintiffs with choosing their best option for compensation.

05. Asbestos Insulation Removal

Safely Removing Asbestos Insulation

Asbestos insulation may still be present in older buildings, factories, equipment and more. Asbestos removal can pose risks and abatement professionals must follow strict guidelines.

Only asbestos abatement professionals should handle, remove and dispose of asbestos and asbestos products. Mishandling asbestos insulation may lead to fibers becoming airborne, increasing the risk of exposure. The EPA recommends the general public not attempt to handle or remove asbestos.

The EPA requires abatement specialists to complete training and certification. These professionals also understand and will follow federal and state laws. These regulations are in place to protect people from asbestos exposure.

Other organizations, such as the CPSC and OSHA also have regulations, rules and requirements in place for handling the mineral.